Key supply chain challenges facing UK businesses

Understanding the hurdles amidst evolving market conditions

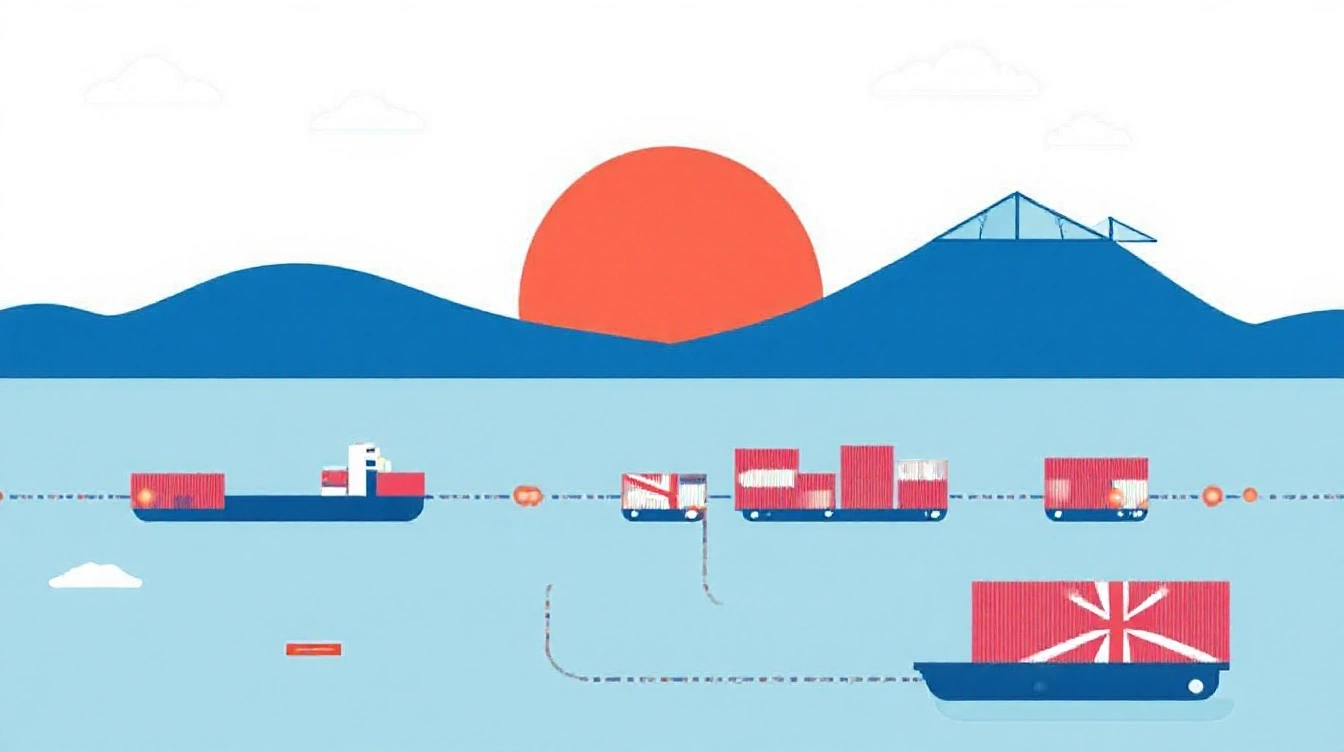

UK supply chain problems have intensified due to overlapping factors such as Brexit impact, COVID-19 repercussions, and global market instability. These aspects create notable logistics challenges that disrupt the timely movement of goods and raw materials across borders.

Also read : How is technology shaping the expansion of uk businesses?

Common supply chain disruptions impacting UK firms include delays at customs, increased tariffs, and workforce shortages. Brexit has introduced new border controls and regulatory complexities, adding friction to previously seamless trade flows within Europe. Combined with pandemic-related factory shutdowns and fluctuating demand, these factors have amplified supply chain fragility.

Sectors most vulnerable to disruption include automotive, retail, and pharmaceuticals. Automotive relies heavily on just-in-time supply models, making it particularly sensitive to delays. The retail sector faces inventory unpredictability, affecting stock availability. Pharmaceuticals contend with stringent regulatory requirements combined with supply shortages, complicating patient care.

Additional reading : Mastering the maze: uk business strategies for thriving amid regulatory shifts

Addressing these UK supply chain problems requires adaptive logistics management and exploring diversified supplier networks. Businesses are encouraged to develop contingency plans highlighting flexibility to mitigate disruptions effectively. Understanding these intricacies empowers firms to navigate ongoing challenges with resilience.

## Innovative strategies to overcome supply chain disruptions

In response to persistent supply chain challenges, UK businesses are increasingly adopting innovative supply chain solutions focused on resilience and flexibility. A critical strategy involves the adoption of new technologies and digitisation to enhance visibility and control. Tools such as real-time tracking, AI-driven demand forecasting, and blockchain for transparency are transforming logistics management, enabling companies to anticipate and react swiftly to disruptions.

Another vital approach is the diversification of supplier bases and risk management. By sourcing from multiple regions and vendors, UK business strategies reduce dependency on single points of failure. This diversification mitigates risks related to geopolitical tensions, natural disasters, or transportation bottlenecks, ensuring a steadier flow of materials.

Additionally, there is a growing emphasis on local sourcing and reshoring production. Bringing manufacturing closer to home not only shrinks lead times but also fortifies business continuity against global transport delays. This trend aligns with a broader push for sustainability and supports regional economies while enhancing supply chain robustness.

Together, these innovative supply chain solutions form a comprehensive framework for UK businesses to navigate complexity and secure operational stability in volatile markets.

Real-world examples of UK businesses responding to disruption

Exploring case studies UK supply chain and innovation

British companies have faced disruption head-on with remarkable business innovation examples. One notable case involved a UK food supply chain company that swiftly restructured logistics amid global delays. By adopting digital tracking and local sourcing, they reduced lead times notably, improving resilience.

In the automotive sector, a prominent UK manufacturer pivoted to electric vehicle components when traditional parts shortages hit. This case study UK supply chain showcased how diversification can turn setbacks into growth opportunities, underlining the value of flexible manufacturing.

Retail success stories often highlight agile responses to changing consumer behaviour. A major supermarket chain enhanced online delivery and contactless payment systems, thriving despite pandemic disruptions. This adaptive strategy offers crucial lessons on leveraging technology and customer engagement.

From these examples, it’s clear UK businesses benefit from swift innovation and learning from both success and failure. Embracing change through proactive supply chain adjustments and technological integration emerges as a common path to overcoming disruption effectively.

Regulatory and market context for supply chain innovation in the UK

Understanding UK supply chain regulations is crucial for businesses seeking to innovate. These regulations ensure safety, transparency, and compliance while fostering an environment conducive to new technologies. The UK government actively supports supply chain innovation through initiatives like funding programs and streamlined compliance processes, which aim to reduce barriers for companies adopting cutting-edge solutions.

Trade agreements and customs processes profoundly impact supply chain operations. Post-Brexit, the UK’s distinct trade agreements require adaptable supply chain strategies to navigate customs efficiently. Businesses must stay informed about these agreements to minimise delays and avoid costly penalties, which can be achieved by leveraging automated customs solutions.

Market trends have shifted towards resilience and sustainability, prompting companies to embrace innovation in logistics, sourcing, and inventory management. The rise of e-commerce, increasing demand for transparency, and the push for environmentally friendly practices compel businesses to rethink traditional supply chains. By aligning with government support and regulatory frameworks, UK firms can position themselves at the forefront of supply chain innovation, enhancing competitiveness in a dynamic market.

Actionable insights for UK businesses seeking supply chain resilience

Building supply chain resilience UK demands a strategic approach grounded in expert tips and best practices. Experts recommend first conducting thorough risk assessments to identify vulnerabilities. This involves mapping out the entire supply chain network, pinpointing potential chokepoints, and evaluating supplier reliability. Tools such as advanced analytics platforms can facilitate this process by providing real-time data and predictive insights.

Once risks are identified, mitigation should focus on diversification—sourcing from multiple suppliers to avoid overreliance—and establishing safety stock buffers. Utilizing digital solutions designed for supply chain resilience UK enables businesses to monitor disruptions and respond swiftly.

Developing a proactive response strategy is critical. This means setting up clear protocols for managing unexpected events, including communication plans with suppliers and contingency measures. Regular scenario planning exercises help prepare teams for rapid decision-making.

Incorporating these expert tips and best practices empowers UK businesses to enhance their supply chain resilience UK, safeguarding operations against future uncertainties and maintaining competitiveness in volatile markets.